The toxic substance contained in exhaust gas as it leaves the engine are known as ‘primary pollutants’, but once they have left the engine some of these may react with each other or with other compound present in the atmosphere to create what are known as ‘secondary pollutants’. Examples of secondary pollutants include ozone, acid rain and photochemical smog.

With all engines, what goes in must come out. If you put in 1kg of fuel and 25kg of air, at the other end the result will be 26kg of exhaust emissions. All the atoms that went in will have come out too, but not necessarily as part of the same compounds they were in before.

In a theoretically perfect combustion, carbon dioxide, water and nitrogen are the end products.

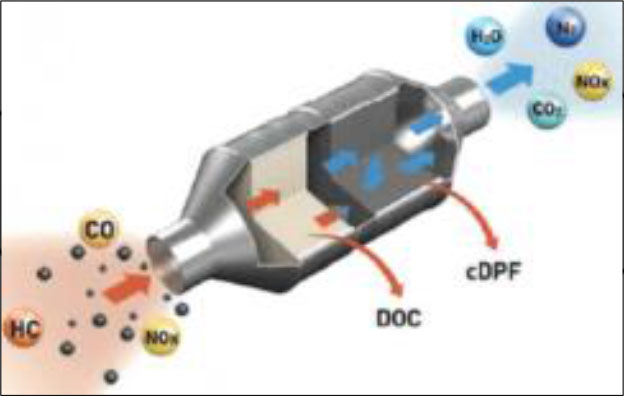

In reality, the incomplete combustion of diesel fuel results in emissions that include oxides of nitrogen (NOx), carbon monoxide (CO), carbon dioxide (CO2), water (H2O) and unburned hydrocarbons (HC). There are also unburned carbon particles, as well as engine oils, soot and ash particulates, which are known as particulate matter (PM).

The diesel particulate matter (DPM) is the visible cloud of black smoke that appears from engine start-up and continues to appear when engine is running.

Before the advent of Diesel Particulate Filters (DPF’s), soot particles are released into the atmosphere at the end of the combustion process causing health and air quality problems. DPF’s are fitted after the catalytic converter to trap these particles. DPF filters also play a small part in the reduction of noise between 10-12DB. The diameter of the soot particles is close to 0.09 microns, which are made mainly by carbon and hydrocarbons. The principle of the Diesel Particulate Filter (DPF) is to collect the sooty particles and periodically burn them off.

It needs to be noted that the lifespan (operation interval) of the DPF/Catalyst combination is between 8000 and 12000 engine hours. The natural combustion of those particles takes place around 550°C. This is known as passive regeneration.

Diesel Emission gasses, that passes thru the Diesel Particulate Filter (DPF):

On site Emission testing and DPM testing with the latest imported Emission test equipment – Infralyt N gas Analyser and a Saxon SMG200M

- HC – Hydro Carbon: Unburnt fuel particles.

- CO – Carbon Monoxide: Partially burnt fuel particles.

- CO2 – A green gas (GHG): By-product of the combustion process.

- NO – Nitrous Oxide: A harmful gas.

- NO2 – Nitrogen Dioxide: A harmful gas.

- O2 – Oxygen.

- DPM – Diesel Particulate Matter: A harmful gas.

Worldwide emission standards are becoming stricter and require improved Catalysts and Diesel Particulate filters specific to the market and individual applications.

Rush Exhaust & Rush Enterprises provide Catalyst and Diesel Particulate filters for power generation equipment and stationary applications complying with all current requirements and future limits.

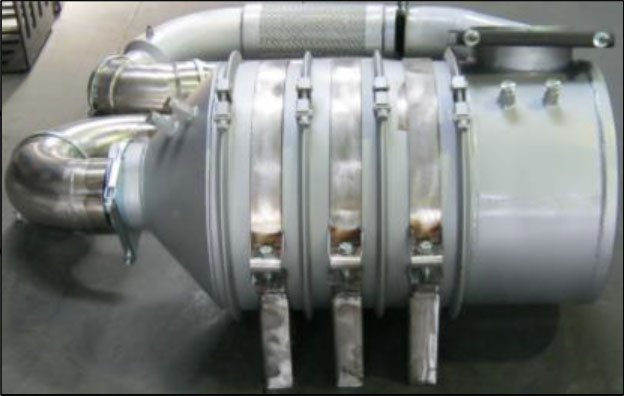

Rush Exhaust & Rush Enterprises develop the newest wash coat formulations and innovative catalyst coatings for applications all over the world. With profound knowledge in the design and technical expertise, co-operation with OEMs, and accredited test labs our R&D achieves an outstanding performance of the catalysts and Diesel Particulate Filters.

We work closely with our customers in order to meet all their requirements and to satisfy their demands. Tailor-made Catalyst and Diesel Particulate Filter solutions and completive precious metal amounts combined with our special coatings result in low light-off temperature, high durability, and performance of our Catalyst and Diesel Particulate Filters.

Our advanced manufacturing equipment allows the coating of standard honeycombs (metallic, wire mesh, and cordierite/SIC) as well as substrates with structured designs.

Rush Exhaust & Rush Enterprise’s patented (Patent No: RP 217451) IMS design proved a significant reduction of PM and all other emissions in many applications. The total PM reduction reached up to 95% in South African and American mining applications with continuous passive regeneration.