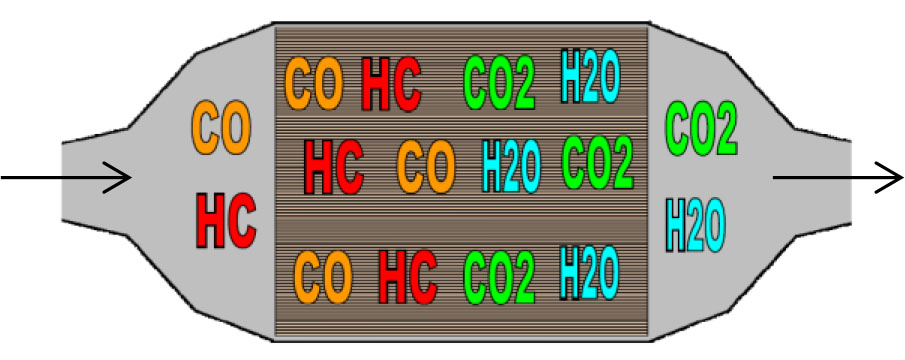

Catalytic Converters / Purifiers are the most popular device for controlling diesel emissions. In a Catalytic Converter / Purifier exhaust pollutants undergo a catalytic reaction with oxygen producing less harmful compounds. They are used in lean mixture diesel engines. (Oxidation) converters burn HC and CO molecules with the assistance of a precious-metals wash coat. This process “converts” these harmful gasses into water vapor and carbon dioxide (CO2) which is nontoxic to humans. It’s important to understand that Converters / Purifiers are most effective when used with engines that have a lean air/fuel mix because this condition provides ample oxygen to “burn” the pollutants. Catalytic Converter / Purifiers almost entirely remove the smell of diesel exhaust.

Catalytic Converters / Purifiers have reductions of:

– Carbon monoxide (CO) from 85-98%

– Hydrocarbons (HC) from 80-95%

– Particulate Matter from 20-95%.

Is an exhaust emission control device that converts toxic gasses and pollutants in exhaust gas from and internal combustion engine into less-toxic pollutants by a process called catalyzing.

Rush Exhaust Purification & Rush Enterprises offer a range of Catalytic converts / Purifiers which are fitted to the customer’s needs, For Example : In Silencers, In case it with cones, we can add flanges or pipe ends. This makes for easy fitment, Bolt on/Off or Clamp on/Off.

- The Catalyst / Purifier eliminate over 85% of carbon monoxide (CO), and Hydrocarbons (HC).

- A Catalyst / Purifier offer’s all the advantages, of a fast start-up, effective emission control and low backpressure, on an average of 3-9 Inch water gauge.

- Removes the smell of diesel.

- Catalyst / Purifier reduce the particular emissions up to 95%.

- High conversion efficiency.

- Excellent mechanical durability, the design is resistant to vibration and axel force.

- A very low pressure drop (only to about1 kPa).